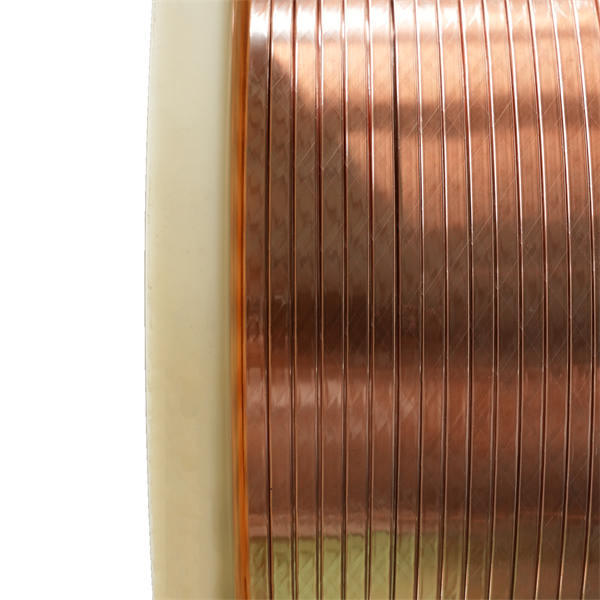

Vinjenje transformatora bakrenom žicom

Električni transformatori su vrlo važan dio električnog sustava, nadam se da to znamo. Već više ne trebaju magnetske polje za pomak energije. Transformatori su svugdje u našem dnevnom životu, od radiove i mobilnih telefona do elektroslučajeva koji stižu u naše kuće i škole. Kako rade transformatori: Sada ćete lako shvatiti tehnologiju iza njih.