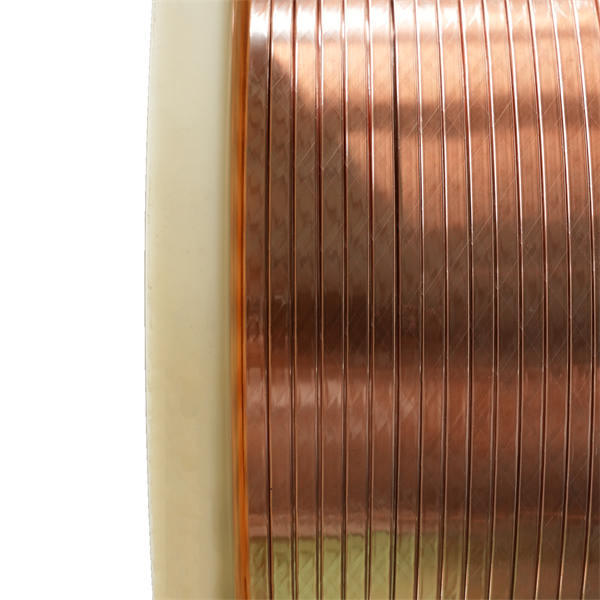

Transformer winding copper wire

Electrical transformer very critical part of electrical system I hope you will know. They no longer need magnets to shift the energy around. Transformers are everywhere in our everyday lives, from radios and cell phones to power lines that reach into our homes and schools. How transformers works: Now you will Understood Easily the technology Behind us.