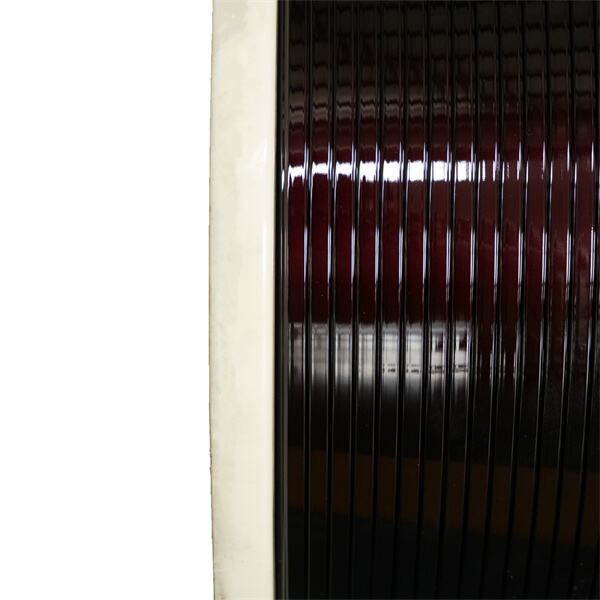

Motor rewind wire

There are a huge variety of motor rewind wire sizes, and types. These can be made out of either copper or Aluminum. The type of wire used depends on what the motor requires. A larger motor needs a thicker wire to carry enough electricity without too much resistance, for instance. If we employ incorrect size wire, this can stress the motor unnecessarily or even kill it.

The rating of the motor rewind wire is known as its gauge, which plays a crucial role in selecting the appropriate size, as well as the YUHENG's electric cable. If we select a proper gauge wire to power the motor, it can damage the engine due to this flow of electricity. This causes melting, where the wire gets hot enough it starts to melt. Should the wire get too hot, it will also ruin the motor and it ceases to operate. why we need to be careful and choose the wire gauge that fits our motor.