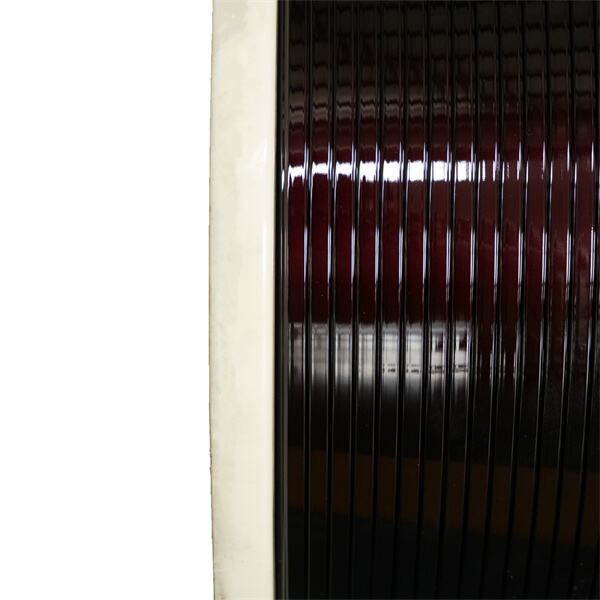

Copper windings in motor

Copper windings for electric machinery are necessary to maintain operating efficiency in a variety of types of equipment such as motors, generators and transformers. YUHENG, is a professional large-scale manufacturer of all types of inverter welding machines, integrating development and production together we have over 10 yap experience in welding field. We’ll take a closer look at the benefits of using copper windings in motors, as well some challenges that pertain to this critical “mechanical heart” equipment.

Due to its mechanical, electrical and physical properties copper windings are preferred in the manufacture of motors. The first reason is that copper makes for a very good electrical conductor, and can effectively conduct the electric current through the motor winding. This high conductance leads to less energy loss, greater motor efficiency and lower costs. In addition, copper windings have a higher thermal conductivity and they are able to evacuate more heat from the motor, thus improving the overall performance of the motor. In addition, copper is a very ductile and malleable material that can be easily shaped from which to form complex coil configurations for maximizing the electromagnetic characteristics of the motor. In general, Copper wire winding in motors results in higher efficiency, and superior quality resulting product.