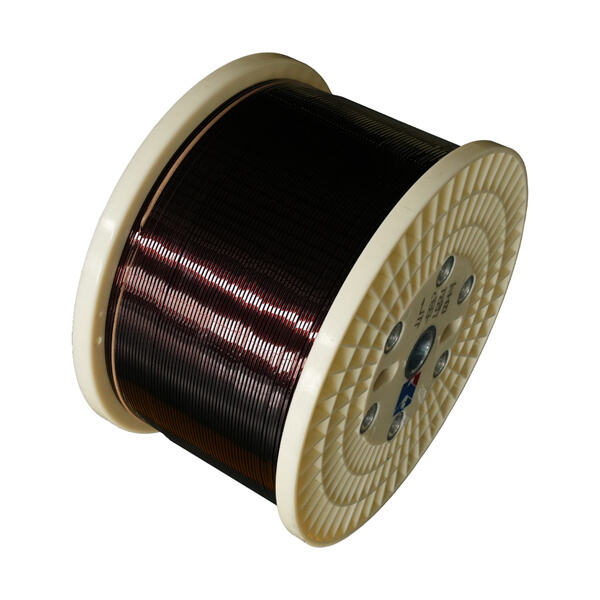

Enameled copper winding wire

When it comes to making electrical appliances such as transformers and motors we make use of one key thing: enameled copper winding wire. This YUHENG enameled copper wire is important as it is coated with a thin layer of enamel that prevents the wire from being damaged by electric current or high temperatures. This shield is crucial in helping the wire to perform and also last a longer time. So, how come enameled copper winding wire would be a good choice!

Cost-Effective – When you are working on projects, you always have to allow a portion of your budget for supplies. That being said, enameled copper winding wire is fairly affordable and performing well so it can be a wise investment choice for cost-savvy consumers.