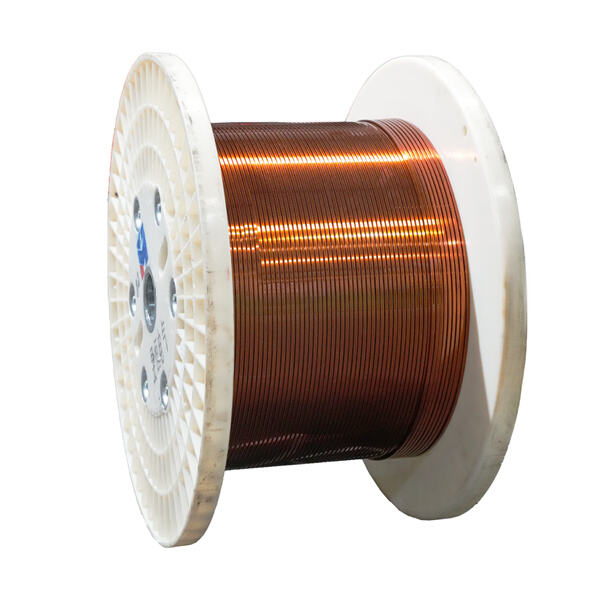

Ceiling fan coil winding wire

It is this neat thing that hangs from the ceiling and makes it so you are not feeling hot if outside happens to be warm out. That is the name of this contraption: ceiling fan This ceiling fan has several small metal wires in it, and these are known as air conditioning unit coil winding wire. The fan won't function at all without this wire so it is definitely a crucial piece. In this blog, we will discuss how long used ceiling fan coil winding wire and why, what you should use the best type of it and some more tips on keeping it working properly in a peak cut-off

The spinning of the fan is greatly assisted by ceiling fan coil winding wire. A fan on a stick - when the spin fans, it creates a gust of air that cools and refreshes you in the stuffy room. This YUHENG coil winding wire is not just a summer solution, but ceiling fans as well can enable the air to move any season. The constant airflow is great as a health benefit and to keep people fresh. Without these wires, the fan would not be able to blow that cool breeze we like when it is hot.