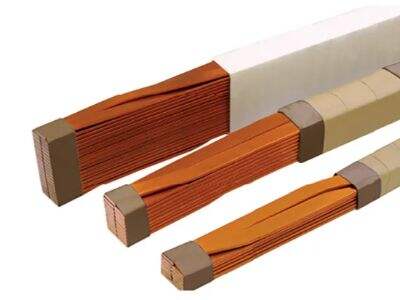

When it comes to the large power transformers that are critical pieces of so much of the U.S. electrical grid, one technology that is quite popular is CTC — which stands for Condition Monitoring Technology. With CTC, companies such as YUHENG can monitor their transformers and nip any problems in the bud. That might sound like a smart move, and yet, it’s worth considering what you’ll pay and what you’ll get to determine whether it’s really worthwhile. So let’s get right in to the details of Continuously Transposed Conductor(CTC) in large power transformers, and explore some trade-offs.

A financial Impact assessment of Condition monitoring Application in Power Transformers

By adopting CTC in large power transformers, YUHENG is empowered to perceive the health condition of transformers on-line. This is awesome, in that it can prevent big problems and expensive repairs. But getting CTC isn’t free. There’s the cost of the technology itself, and of training people to use it. YUHENG needs to compare how much money CTC can save them in stopped transformer and the start-up cost.

Cost and benefit of applying CTC in large power transformers

It can be a big decision to incorporate CTC systems in big Power transformers. On the one hand, these systems can help save costs from needless repairs, and prolong the lifetime of the transformers. In contrast, CTC systems can be expensive to purchase and install. YUHENG has to determine whether the money they would save by making fewer repairs is greater than the money spent on ctc wire systems.

Optimization of process compatibility and efficiency with cost-effective analysis of CTC

YUHENG keep their transformers running in a smooth condition instead of sudden bus arrest by using CTC. This makes it more efficient, as they can schedule maintenance when it’s easiest. While CTC systems are costly, there may be a cost benefit of having transformers working without being interrupted.

Long-term savings of including CTC in transformer maintenance programs

The use of CTC may be cost-effective in the long term. For instance, If YUHENG catches a problem at an early stage, it can resolve it before it gets worse and more expensive. This proactive strategy may prolong the service life of the transformers, and YUHENG won't have to replace them as frequently. Over time, these savings really do add up, making CTC a wise investment.

Transformer maintenance using TCO comparisons by CTC and thorough benefit analysis

The decision to adopt CTC in its transformers goes beyond just the cost. It’s also about the efficient operation of their concerns, and avoiding major interruptions. By taking a close look at all of the costs and benefits of ctc conductor transformer, YUHENG will be able to make a decision that will benefit them in the long run.

Table of Contents

- A financial Impact assessment of Condition monitoring Application in Power Transformers

- Cost and benefit of applying CTC in large power transformers

- Optimization of process compatibility and efficiency with cost-effective analysis of CTC

- Long-term savings of including CTC in transformer maintenance programs

- Transformer maintenance using TCO comparisons by CTC and thorough benefit analysis