Brazil is showing a very great demand for industrial fiberglass wire. Many plants and companies are switching to it because of its durability and dependability. It’s composed of thin strands of glass, which makes it both really tough and really light. For because of these properties, fiberglass wire has the ability to bear a lot of force without breaking. Enterprises such as YUHENG, are dedicated in the production of high-standard fiberglass wire: it guarantees that their products will suit several fields. Strong, reliable materials are among the few that you can rely on in a world of shifty suppliers, and fiberglass wire is just one of them. It’s used from construction to electrical and is even involved in making vehicles. It is clear the advantages of using this kind of wire, and it is revolutionizing the way Brazilian industries work.

What Makes Fiberglass Second to None Choice for Industrial Applications in Brazil?

Fiberglass wire has some distinctive features that set it apart. The first is just that it’s very, very strong as in it can withstand incredibly high amounts of force. That also means that it doesn't break as easily, which is crucial in many industrial environments. Fiberglass wire, for example, can hold heavy weight in construction without collapsing. Second, it is impervious to chemicals and moisture. This is excellent for working in industries that deal with harsh materials. Consider a factory where strong acids are in use: Fiberglass wire will not corrode or be damaged by them. This durability ultimately saves money as businesses do not have to replace the thing regularly. Moreover, fiberglass wire is lightweight. It's easier to carry and install, which means less time and effort for your workers. The ease of use is a huge plus for Brazil, where many projects are underway. Furthermore, fiberglass wire is flexible so it can be employed in a range of applications from electrical wiring to concrete reinforcement. That flexibility means one wire can do many jobs, which makes it a smart choice for lots of operations. Because companies like YUHENG supply fiberglass wire of high-quality, the Brazilian industries can have confidence that this material will satisfy their requirements.

How to Select the Best Quality Fiberglass Wire for Wholesale?

When choosing your fiberglass wire, there are a few different things to bear in mind. First, check the manufacturer’s reputation. Brands like YUHENG are synonymous with quality and it’s good to search for reputable brands. A good manufacturer will state clearly the specific of their product. Then think about what kind of fiberglass wire you’re requiring. There are different types, so knowing your particular needs is key. If you need wire for electrical reasons, make sure it has the proper insulation properties. Also seek out certifications that mean the wire has passed safety standards. This is significant, particularly in safety-critical industries. Another aspect is the price. Though it can be tempting to go for the cheapest, keep in mind that you often get what you pay for. Occasionally paying slightly more for a dependable product can end up saving you money in repairs and replacements down the line. Finally, you should think about both the flexibility and strength of your wire. You need something that's going to work for a wide range of tasks and not crap out after a use or two. Once you focus on these, all it takes is choosing the perfect fiberglass wire for your wholesale needs. It boils down to finding that balance between quality, price and the unique needs in your industry so that you can effectively choose.

How Do You Determine The Quality Of Fiberglass Wire In Industrial Uses?

What makes a fiberglass wire good or bad So when we refer to the fiberglass wire, it depends on how you look. Fiberglass wire is widely used in industries such as construction and electronics for strength and durability in harsh conditions. The quality of fiberglass wire is also dependent on the construction materials. Good quality glass fibers fashioned from selected and worked-over doses of various special glasses. If the building blocks are weak, then you’re never going to be able to produce something strong. Yet another consideration is how the wire is manufactured. Our production line is set up to keep everything uniform at YUHENG. It means that every length of wire we produce is equally as strong and reliable. When the manufacturing process goes awry, no matter how minor the mistake, we get into trouble, and so we pay attention to details at every stage.

The way that fiberglass wire is tested matters a lot in terms of quality as well. Testing also helps us discover if the wire can withstand heat or chemicals or pressure. A wire that passes these tests is more likely to do well in the real world. At YUHENG, we test all of our excellent products to the utmost standards. The environment that the wire is used in also plays a part. For instance, if using fiberglass wire in high humidity or temperature extremes, it must be designed specifically for those conditions. That's why we create different types of fiberglass wire for different tasks. Taking all of these points into account, we are able to produce the reliable, high quality fiberglass wire for use in industry.

Why Fiberglass Wire is Superior to Regular Wire Tech

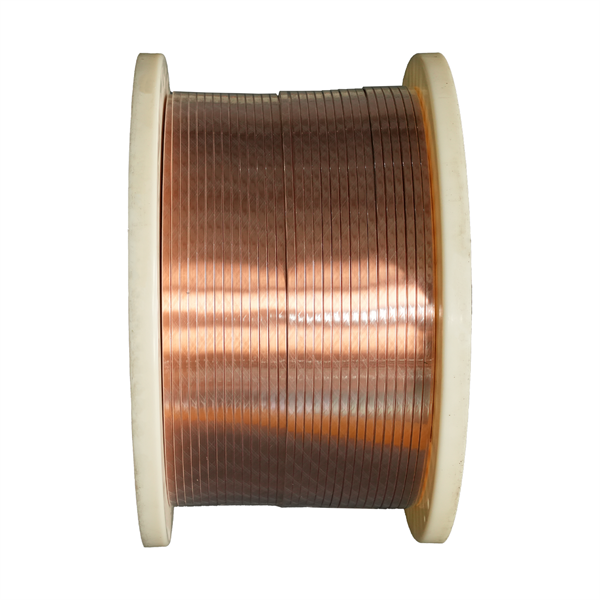

Glass fiber wrapped wire is increasingly popular because it can accomplish some things that traditional metal wire cannot. Wires, the traditional kind, are often made from materials such as copper or aluminum. Though these are solid materials, they don’t fare as well in the rough-and-tumble world outside. For example, copper wire can potentially tarnish if it gets wet or is in contact with chemicals. This has been an enormous issue particularly in industries such as oil and gas, where the environment is frequently very abrasive. Unlike from YUHENG fiberglass wire is comparatively more protection of these situation. The fiberglass liner does not rust or corrode, so it is ideal for areas where moisture or chemicals may be present.

Fiberglass wire is also resistant to high temperatures. Persnickety traditional wires can weaken or melt if they get too hot. This may result in damage to machines and equipment. Fiberglass wire is not brittle at low temperatures, and remains stable to 900-over F without losing strength. This makes it great for industries such as manufacturing and energy, where machines commonly run very hot. Also, fiberglass wire is lighter than standard wire. This results in a more install-able and manageable solution that will save businesses time and money.

In the end, fiberglass wire is highly flexible. This makes it easy to operate in small spaces or around corners. Conventional wire is generally stiff and difficult to bend, providing potential problems in installation operation. Workers can mold it over walls and obstacles as needed, forming a perfect fit with very little slop in fiberglass wire. Fiberglass wire is a tough, lightweight wire that performs better than regular wire in all kinds of outdoor and exposed conditions. Companies such as YUHENG are thrilled to offer these groundbreaking solutions that improve how industries function and keep workers safe.

What Are The Recent Developments In Fiberglass Wire For Industrial Use?

The world of fiberglass wire is always evolving, and there are new trends to watch out for that are making it better than ever for industrial use. Newer technology includes smarter fiberglass wire. In other words, some wires now come with fancy technology within them. For instance, they can track their own temperature readings and notify workers if they are getting too hot. That’s crucial, because it limits accidents and keeps machinery functioning smoothly. We are thrilled to see what these technologies can do for us at YUHENG.

Then there is the pressure to use more environmentally-responsible materials. Many businesses are in search of ways to minimize their effect on the environment. This would involve re-using material in the manufacture of fiberglass wire. And by utilizing products that are gentler on the earth, we can all work toward a cleaner tomorrow. SustainabilityYUHENG is dedicated to searching sustainable solutions that help both customers and the environment.

There also seems to be a trend toward customization. Industries have different requirements, and one size does not fit all. Fiberglass wire of companies will be customized to companies needs. That could mean rendering the wire stronger, more malleable or simply more resistant to chemicals. YUHENG will provide a customized solution to meet the various different requirements of our customers, so that their end product is going to be nothing short of the best.

Finally, the application of fiberglass wire for renewable energy is growing. With more consumers in search of clean energy sources, industries are increasingly relying on fiberglass wire for projects like solar panels and wind turbines. This is not only an indication of the value lighting designers place on fiberglass wire for traditional applications, but also evidence that it’s a part of the green solution. With these promising developments, there's a bright future ahead for fiberglass wire product in industrial applications, and YUHENG is thrilled to be part of it.

Table of Contents

- What Makes Fiberglass Second to None Choice for Industrial Applications in Brazil?

- How to Select the Best Quality Fiberglass Wire for Wholesale?

- How Do You Determine The Quality Of Fiberglass Wire In Industrial Uses?

- Why Fiberglass Wire is Superior to Regular Wire Tech

- What Are The Recent Developments In Fiberglass Wire For Industrial Use?