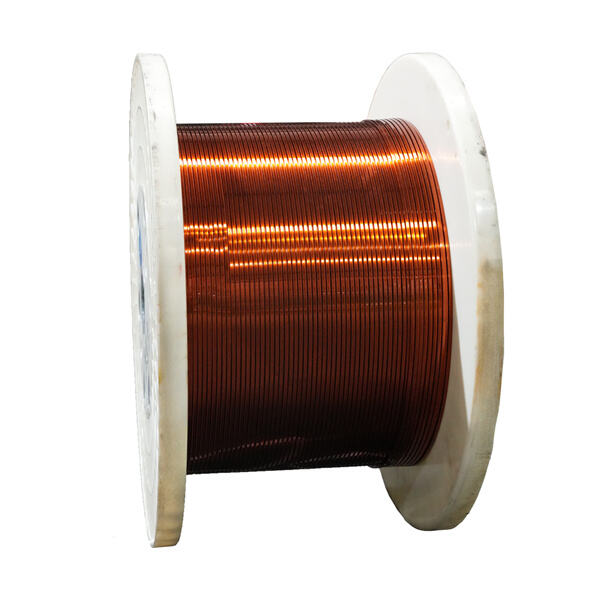

Wire enamelling

High Quality Wire Enameling Service We’re the perfect choice for wholesalers who need reliable, long-lasting products at competitive prices. Our wire enamelling process means the wire is layered with a protective coat to reduce the risk of rusting and increase its life span. For all your wire requirements -Whether it be for Industrial machine or electric application YUHENG have you covered with our quality enamelling.

If you are looking for a professional top quality wire enamelling sticker provider, then it is the one that until now all company trust. Our organization is well recognized firm in providing of a quality array of copper wire enameled. As one leader in the field of industrial manufacturing, we offer a variety of professional services to guarantee you quality throughout. Furthermore, our dedication to innovation and evolution makes us a unique supplier in the market.