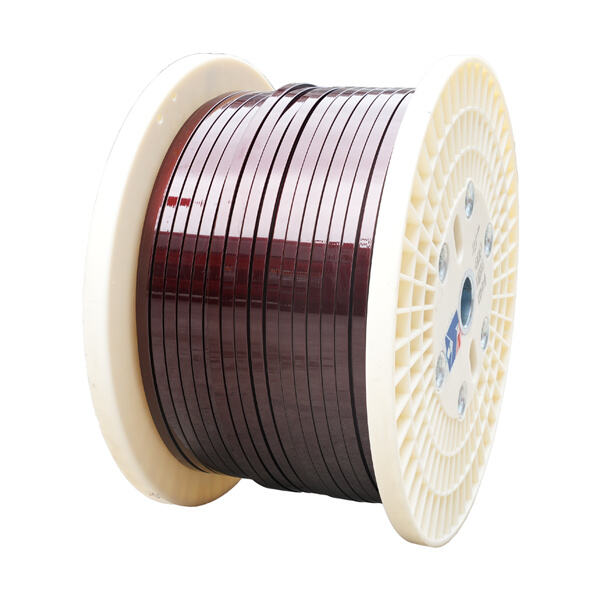

Enamel wire

For industries that require high voltage, such as transformers or motors, enamel wire does the heavy lifting. Enamel insulation of the wire, prevents electricity leakage or short circuits. This is to guarantee that the machine can work safe and reliable, without any problem. We are a credible manufacturer in China.

For commercial applications, wholesale enamel wire suppliers are critical to public companies providing the needed product to operate their business. These vendors have a variety of enamel wire for you to choose from, depending on what suits your needs best. YUHENG is a high-quality enamel wire supplier, and has been for years. With YUHENG as your partner, you can be confident that our top quality enamel wire products are perfectly matched to the needs of any industry.