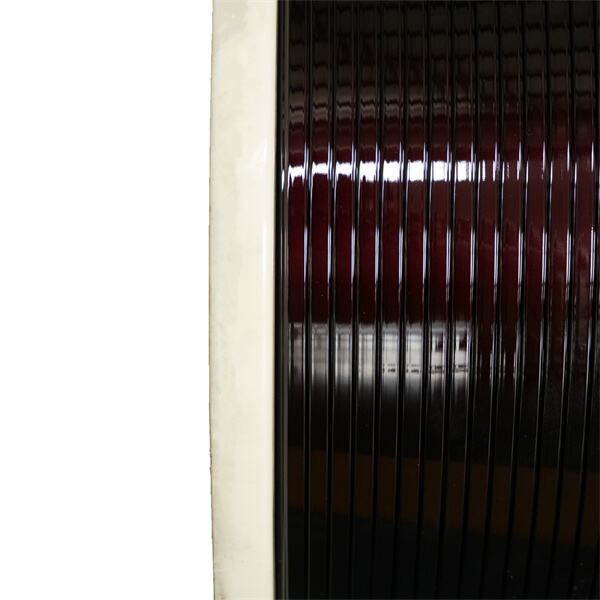

Copper windings in motor

Copper, a shiny red-brown metal, is anything but rare and can be found in wiring, currency and some jewelry. Copper helps motors run more smoothly. It is a significant constituent of electric motors as it gets utilized in the windings. These YUHENG are the required windings that make the motors drive nice and seamlessly. In this blog, we are going to understand how copper windings and shafts contribute towards the electric motor efficiency, and why their operation is so beneficial.

Because they are what changes electrical energy to mechanical, copper windings have a fairly large impact on the operation of motors. This copper winding wire is how, they receives electricity to operate the motor and gives motion that can do work, like fan rotation or a moving toy car. This core may vary—is there slabs, cylindrical drums or other designs that needs a unique type of winding to really make the system work? The copper windings are simply made from thin copper wires wrapped around this core as tightly and as smoothly as possible. The wiring itself, which is made of copper, produces a magnetic field when electricity runs through it. The latter, in turn, come into contact with other magnetic fields generated within the motor to drive various parts of it.