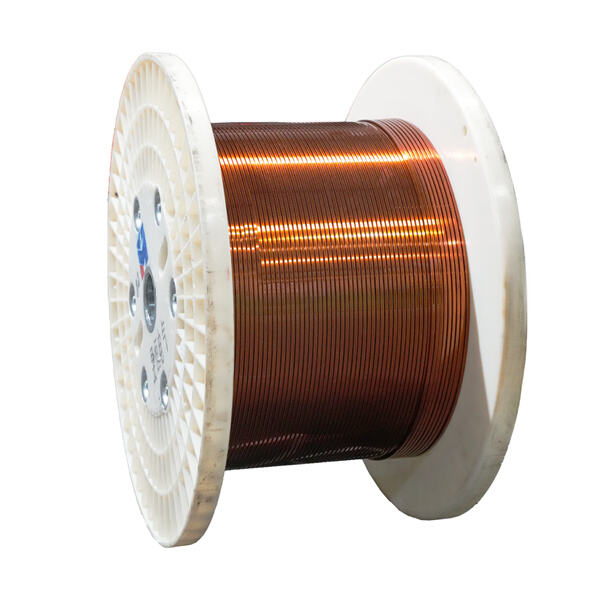

Breakdown voltage of enameled copper wire

Enamelled copper wire is used in several types of electrical applications due to its high break down voltage. Knowledge of the common usage problems in enameled wire breakdown voltage contributes to reliable and safe use purpose in electrical systems with this type of insulation. The risk of such situation is a decrease, over time, of the breakdown voltage because of temperature effects, humidity, mechanical stress etc. These environmental conditions can deteriorate the insulation of the wire, resulting in a decrease in breakdown voltage and potential electrical faults.

Some frequently encountered usage problems of the breakdown voltage of enamelled copper wire can be reduced by reasonable handling and storage. For instance, keeping the wire in a cool and dry place can contribute to preventing degradation of the insulation material, and hence maintaining the breakdown voltage after a certain period of time. Further, if the wire's insertion in installation is such that it has not excessive bending or twisting during such installation this can also avoid mechanical stress which might damage its insulation. Regular examination and testing of the enameled copper wire can also prevent any problems, locating potential breakdowns in a system's electrical currents before they even begin.