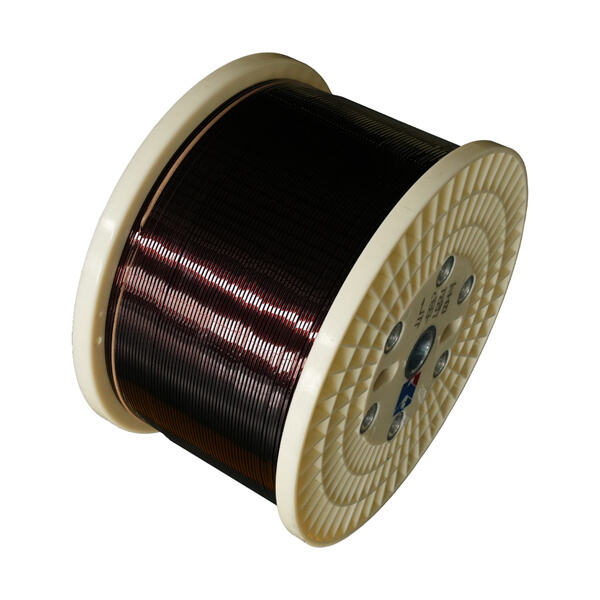

24 awg magnet wire

Choosing the right wire when you are doing electrical projects. Choosing the right kind can make a real difference in how well your project operates. 24 AWG magnet wireOne of the more popular types of wires people use. This wire ranks high in strength and dependability, making it a top choice for advanced as well as novice hunters. Today, we will dive into 24 AWG magnet wire and who uses it, different types of the wiring on the market and so much more.

Power Consumption: Also YUHENG magnet with copper wire can easily let the current pass through it so gives power consumption efficiency. It is an important property for the normal function of every electronic. Without a good flow of electricity, devices may stop acting the way they should. Also, this wire does not corrode which enables it to maintain corrosion for a longer time period. Its resistance to high temperatures also makes it perfect for working in the all kinds of tough industrial environments and environments in which things are hotting up.