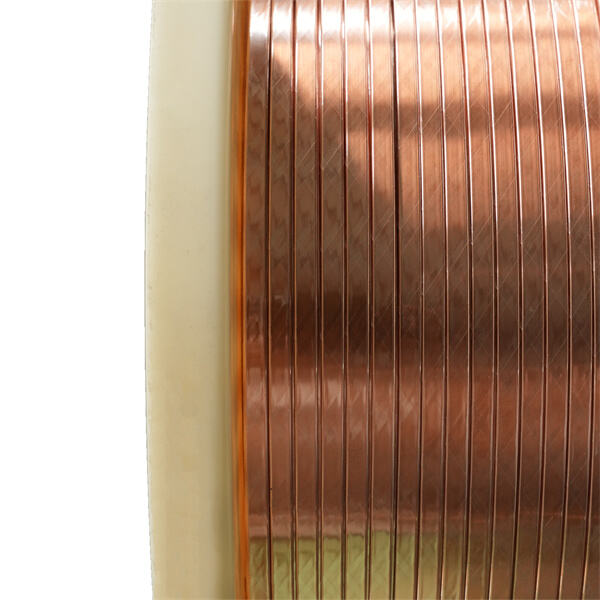

18 gauge magnet wire

The use of 18 gauge magnet wire has several advantages in industrial situations. One of the benefits is its efficient ability to conduct electricity that already corresponds with it's gauge size. This makes the transformer less likely to overheat and perform better in high-load applications such as motors, transformers and other electrical equipment. Furthermore, the copper wire for motor winding is thin and flexible to facilitate installation and routing thereof whereby handling time during manufacturing of the circuit device is greatly reduced. Its robustness, combined with its resistance to wear and abrasion, and corrosion guarantee reliable performance over time with a lower cost of serviceability and machine downtime.