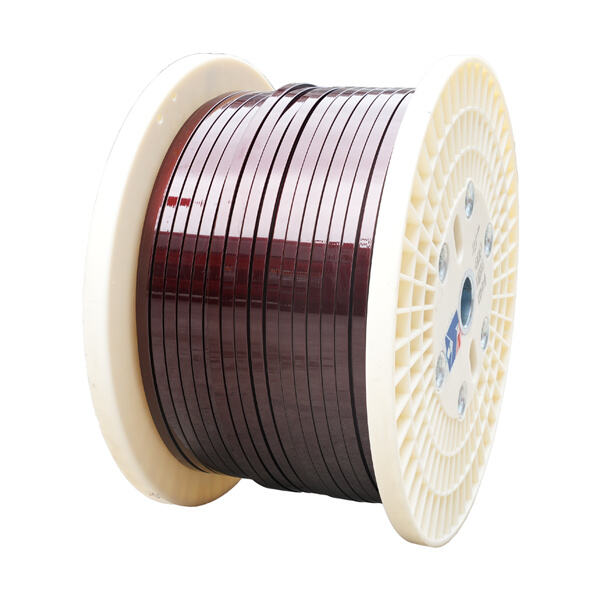

14 gauge enameled magnet wire

If you are working on a project with wire I would recommend using 14 Swg enameled copper magnet wire. Its applicable for this wire since it has a coil of enamel coated on the surface. They have a thin covering; this works as an insulating material that will safeguard the wire and maintain it from becoming damaged. The coating of the wire will also add some super-strength to it as well with made out of a enamel. And some of them are listed as follow, but we will talk about only the major advantages of the 14 gauge enameled magnet wire

The best thing about 14 gauge enameled magnet wire is that it can manage to take high heat as well. Therefore, this can be a good option for use in motors and transformers or any other equipment which heats up while functioning. This YUHENG enameled copper wire insulation helps prevent melting or burning of the wire due to shielding. This way, your project will be more durable and able to work properly instead of running out.